New Holland 667TA EEG

New Holland 667TA EEG, 667TA EDJ Engine Manual

Overview of the New Holland 667TA Models

The New Holland 667TA EAG and 667TA EDJ models represent cutting-edge engineering in heavy machinery. These robust engines are designed to deliver exceptional performance while maintaining fuel efficiency, making them ideal for various applications.

Key Features and Benefits

Both the 667TA EAG and 667TA EDJ engines boast advanced technology that ensures reliability. Features include enhanced air filtration systems and improved cooling mechanisms, which contribute to an overall longer lifespan.

Accessing the Engine Manual

Owning the New Holland 667TA engine manual is essential for proper maintenance and troubleshooting. This valuable resource provides detailed instructions, ensuring optimal performance and longevity of your engine. Stay informed and enhance your equipment’s performance with comprehensive guidance.

Engine Manual for 667TA/EEG, 667TA/EEC, 667TA/EBF, 667TA/EED, 667TA/EBJ, 667TA/EDJ

Issued 11-2006

Book/Form Number 87519804 NA

Service Manual

Number of Pages: 150 Pages

The New Holland 667TA EEG and 667TA EDJ Engine Manual is an essential guide for servicing and maintaining these diesel engines, commonly used in various agricultural and industrial machinery. The manual covers detailed instructions for repair, routine maintenance, and troubleshooting of the engines to ensure they operate at peak efficiency.

Engine Overview and Specifications

This section provides an overview of the 667TA EEG and 667TA EDJ engines, including:

- Technical specifications: Details such as engine displacement, horsepower, torque, and compression ratios.

- Component locations: Diagrams showing the layout of major engine parts like the fuel system, cooling system, and exhaust components.

Routine Maintenance Procedures

To maintain optimal engine performance, the manual outlines routine maintenance tasks, including:

- Oil and filter changes: Step-by-step instructions for draining engine oil, replacing oil filters, and refilling with the recommended oil.

- Coolant system checks: Instructions for inspecting the radiator, hoses, and coolant levels, as well as flushing and refilling the system.

- Air and fuel filter replacement: Guidelines on when and how to change the air and fuel filters to prevent clogs and ensure proper airflow and fuel efficiency.

Fuel System Maintenance and Repair

The fuel system section covers:

- Injector servicing: Cleaning or replacing fuel injectors to ensure efficient fuel combustion.

- Fuel pump adjustment: Procedures for diagnosing and repairing fuel pump issues, ensuring optimal fuel delivery to the engine.

Cooling System Repair

The cooling system is crucial to prevent overheating, and the manual includes:

- Radiator inspection: Instructions for checking for leaks, cleaning the radiator, and ensuring proper coolant flow.

- Water pump and thermostat replacement: How to service or replace faulty components that may lead to overheating.

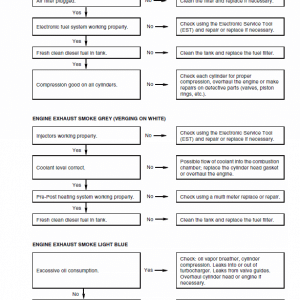

Troubleshooting and Diagnostics

The manual offers a comprehensive troubleshooting guide to help identify common engine issues such as:

- Starting problems: Diagnosing and fixing battery, starter, or fuel delivery issues that affect engine start-up.

- Power loss: Steps to identify and repair problems related to air intake, fuel delivery, or exhaust systems causing a reduction in power.

Electrical System

The electrical system section covers:

- Battery maintenance: Checking voltage levels, cleaning terminals, and replacing worn or damaged batteries.

- Starter motor and alternator checks: Procedures for testing and repairing electrical faults related to engine start-up or charging.

Engine Manual TABLE OF CONTENTS

Chapter 1

Diagnostics

Table Of Contents

Cnh- Est Diagnostic Tool

Troubleshooting

Chapter 2

667Ta Engine Overhaul

Table Of Contents

Engines

Coding Of Source Engines

Engine Properties

General Engine Features

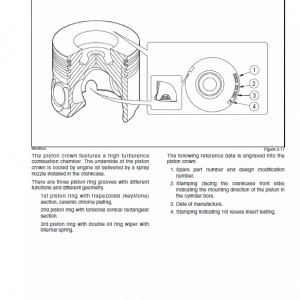

Crank Gear Components And Cylinder Assembly

Valve Gear – Cylinder Assembly

Torque Specifications

Special Tools

667Ta Engines

Description Of Main Engine Components

Egr Exhaust Gas Recirculation System

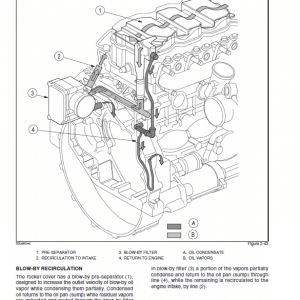

Engine Lubrication

Engine Cooling

High Pressure Electronic Injection System (Common Rail)

Edc7Uc31 -Electronic Control Unit Operation

Fuel Supply System

Common Rail

Common Rail Pressure Relief Valve

Electro-Injector

Location Of The Main Electrical Components

Checking The Fuel System

Engine Overhaul On The Bench

Checks And Specifications On Engine Crankcase

Crankshaft

Engine Flywheel

Cylinder Head

Valves

Valve Guide

Valve Seats

Valve Springs

Cylinder Head

Rods And Tappets

Chapter 3

Charging And Start-Up

Table Of Contents

Starter Motor

Alternator

Reviews

There are no reviews yet.