Case 9020B Excavator Factory Service Manual

Total workshop & service guidebook with electrical circuitry layouts for Situation 9020B Excavator. It coincides service handbook utilized by dealerships that guaranteed to be totally useful and undamaged with no missing web page.

Excavator Model: 9020B

Publication Number: 7-63072

April 1999

Format: PDF

Language: English

- Case 9020 Excavator Service Manual – 1093 Pages

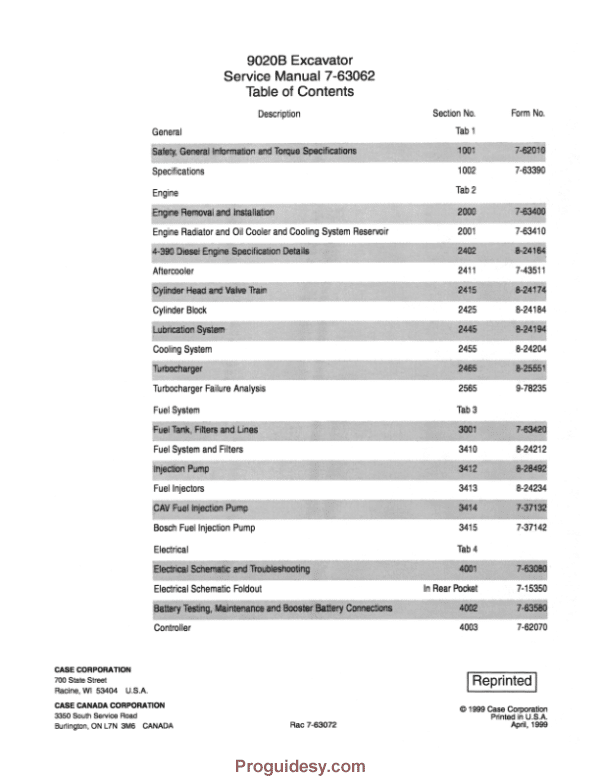

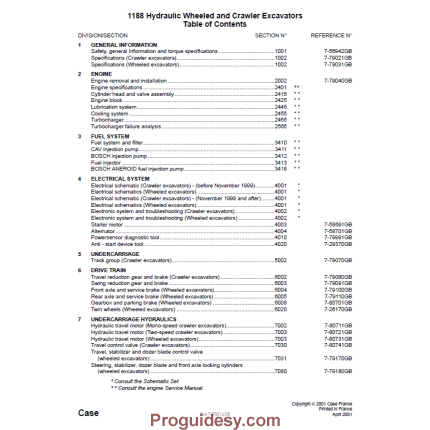

Manual Table of Content:

General

Engines

Fuel System

Electrical

Steering

Power Train

Hydraulics

Mounted Equipment

Hydraulic and Electrical Schematics

Case 9020b repair

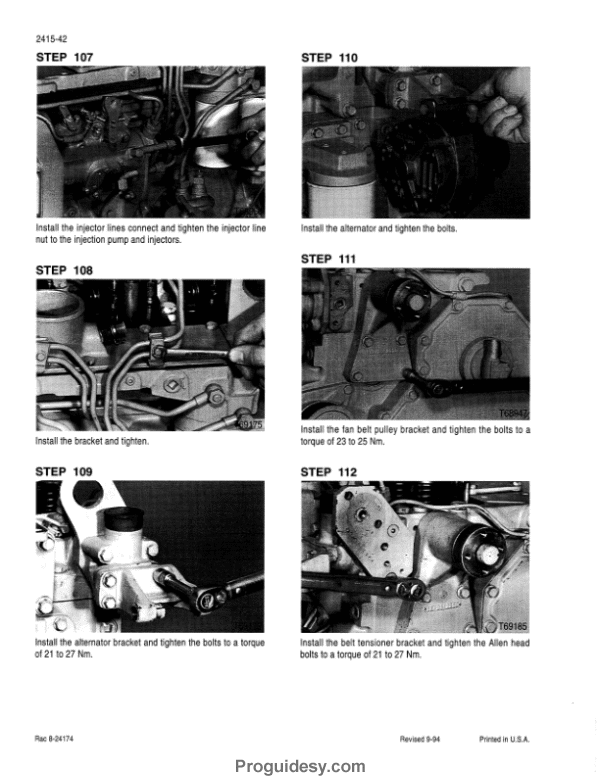

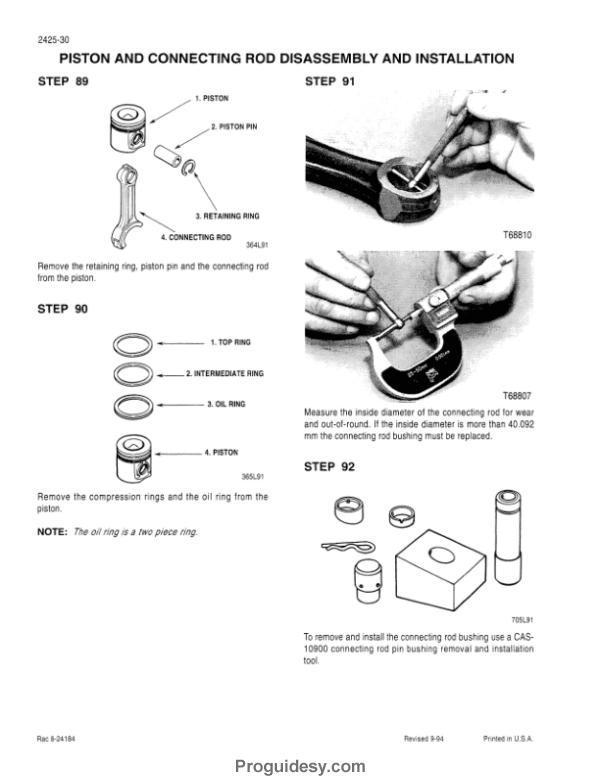

This Instance 9020B Excavator service & fixing guidebook (including maintenance, overhaul, taking apart & assembling, change, tune-up, operation, checking, diagnostic & troubleshooting …) is split into various sections. Each section covers a particular part or system with in-depth images. A table of contents is positioned at the beginning of each section. Pages are conveniently discovered by category, as well as each web page is expandable for terrific information. The printer-ready PDF documents work like a beauty on all kinds of devices.

case-63062 – 90208

EXCERPT:

TRACK

Removal

ACTION 1

Park the device on a difficult degree surface. Revolve the upper framework of the equipment to ensure that the taxi is over the track to be eliminated.

ACTION 2

Lower the bucket or tool to increase the equipment till the track to be gotten rid of is one to two inches from the ground.

NOTE: If the maker does not have a pail or tool mounted, Mount wood blocks under the arm and also reduced the arm into the wood blocks. After that, reduced the arm to increase the equipment.

STEP 3

Master pin is determined by the opening in the facility of the pin as well as retainer pin on opposite end.

Operate machine up until master pin is near facility of gear.

Operate device to lower track to be eliminated to ground.

Revolve the upper structure of the equipment to make sure that the taxi is facing the front. Quit the engine.

STEP 4

DO NOT remove the check valve. The oil in the track adjustment cyndrical tube ls under high pressure. Loosen track as much as possible by gradually loosening up the check shutoff to release oil pressure up until the grease moves from the adjustment cylinder (about two turns). Grease will certainly stream from a groove in the check shutoff.