Timberjack 608 Carriers Service Repair Manual

The Workshop Manual is intended to provide technical information, component specifications, troubleshooting and removal, disassembly and re- assembly procedures for most of the major components of the 608 Carriers which include 608 Feller Buncher, 608/T J3000 and the 608 Alternate Head.

Model: Timberjack 608

Type: Carriers Logger

Language: English

Format: PDF

- Timberjack 608 Carriers Service Repair Manual – 428 Pages

Timberjack 608 Carriers Manual Table of Content

Description

Introduction and Specifications

Power Unit

Power Train

Brake Systems

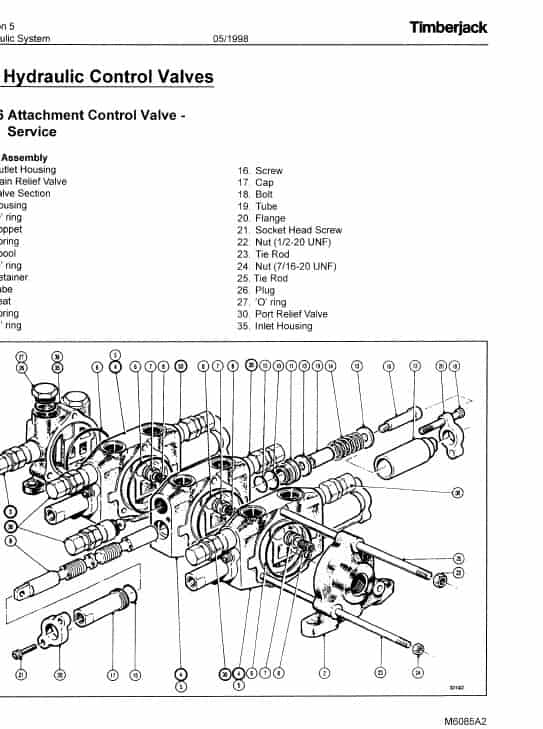

Hydraulic System

Electrical System

Heating and Air Conditioning

Timberjack 608 Carriers Service Repair Manual

The Workshop Manual is intended to provide technical information, component specifications, troubleshooting and removal, disassembly and re- assembly procedures for most of the major components of the 608 Carriers which include 608 Feller Buncher, 608/T J3000 and the 608 Alternate Head.

Certain components such as the engine, felling head, harvesting head, fire suppression system and optional equipment are covered in individual manuals provided by the respective manufacturers. For specifications, parts listings and servicing procedures these manuals should be obtained to supplement the Workshop Manual.

When practical the Workshop Manual lists likely causes of malfunctions, offers test procedures to verify causes and then illustrates the steps for the adjustment or repair procedure(s).

Since it is never possible to anticipate all of the possible failure or malfunction scenarios, a concerted effort has been made to explain the function of or method of operation of many complex components. This information can be used to predict other causes of machine malfunction.

Troubleshooting must always be a multi step process. Use the following steps:

1. Know the operation of all machine systems.

2. Ask the operator about symptoms and when they occur.

3. Operate the machine yourself if practical.

4. List all possible causes.

5. Inspect the machine for obvious causes.

6. Eliminate the simple ones by checking oil, changing filters, etc.

7. Carry out diagnostic procedures like pressure, leakage and slippage testing to pin point the cause.

Reviews

There are no reviews yet.