Komatsu 3.1522, 3.1524, T3.1524 Diesel Engines Manual

Komatsu Engines

Publication: 4799 008 M1

Format: PDF

Language: English

Komatsu 3.1522, 3.1524, T3.1524 Engines Service Repair Manual – 98 Pages

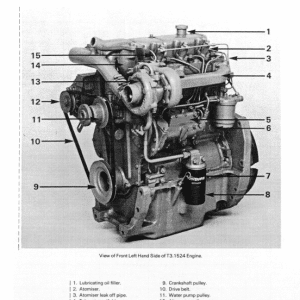

Below is an actual picture of the engine:

The Komatsu 3.1522, 3.1524, and T3.1524 Diesel Engines Manual is a comprehensive guide that provides detailed instructions for the maintenance, repair, and servicing of these diesel engines. It is an essential resource for technicians, operators, and service personnel to ensure optimal performance and longevity of the engines. Here’s a breakdown of the key sections of the manual:

Engine Overview and Specifications

This section introduces the key features and technical details of the 3.1522, 3.1524, and T3.1524 diesel engines, including:

- Engine specifications: Engine displacement, horsepower, torque ratings, compression ratios, and fuel efficiency.

- Component identification: Diagrams and descriptions of key engine components, such as the cylinder head, fuel system, cooling system, and exhaust system.

Routine Maintenance Procedures

Regular maintenance is essential to keep the engines running smoothly. This section covers:

- Oil and filter changes: Step-by-step instructions for draining engine oil, replacing oil filters, and refilling the engine with the correct oil type.

- Air filter replacement: Guidelines for inspecting and replacing air filters to ensure efficient airflow and combustion.

- Fuel filter maintenance: How to replace fuel filters to prevent fuel contamination and ensure smooth engine operation.

- Coolant system checks: Instructions on inspecting, flushing, and refilling the cooling system to avoid overheating.

1. Composition of shop manual

This shop manual contains the necessary technical information for services performed in a workshop. For

ease of understanding, the manual is divided into the following sections.

00. FOREWORD

This section explains the safety and basic information.

10. STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

This section explains the structure, function, and maintenance standard values of each component.

The structure and function sub-section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly and service.

20. TESTING AND ADJUSTING

Standard value table

This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

Testing and adjusting

This section explains measuring instruments and measuring methods for testing and adjusting, and method of adjusting each part. The standard values and judgement criteria for testing and adjusting are explained in Testing and adjusting.

Troubleshooting

This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The S mode of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

Reviews

There are no reviews yet.