Komatsu WA350-1 Service Repair Manual

FOREWORD GENERAL

This Komatsu shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgments. Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding of the structure but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at the completion of the checks and repairs. Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

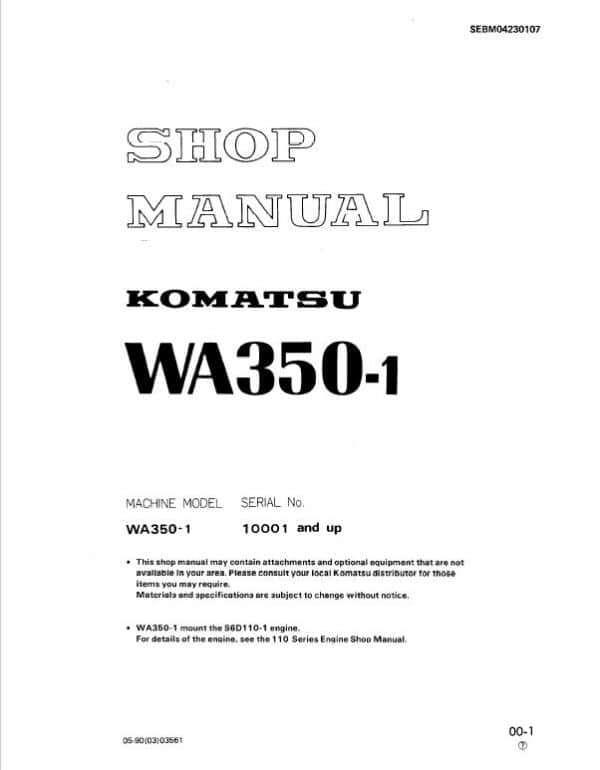

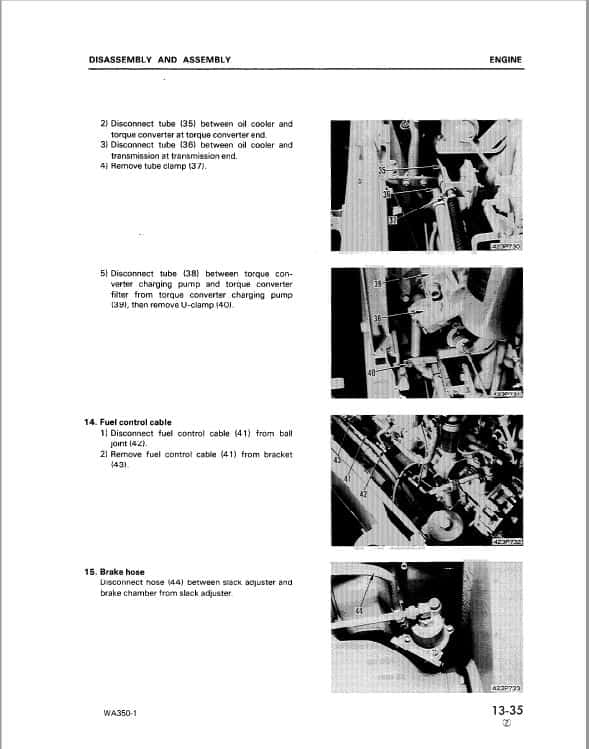

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component, as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in STRUCTURE AND FUNCTION.

Komatsu WA350-1 Service Repair Manual

Manual Table of Content:

10 ENGINE

20 POWER TRAIN

40 STEERING SYSTEM

50 BRAKE AND AIR SYSTEM

60 WORK EQUIPMENT SYSTEM

80 ELECTRIC AND ELECTRONIC SYSTEM

90 OTHERS

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

CONTENTS

10 ENGINE

11 STRUCTURE AND FUNCTION

12 TESTING AND ADJUSTIN

13 DISASSEMBLY AND ASSEMBLY

20 POWER TRAIN

21 STRUCTURE AND FUNCTION

22 TESTING AND ADJUSTING

23 DISASSEMBLY AND ASSEMBLY

24 MAINTENANCE STANDARD

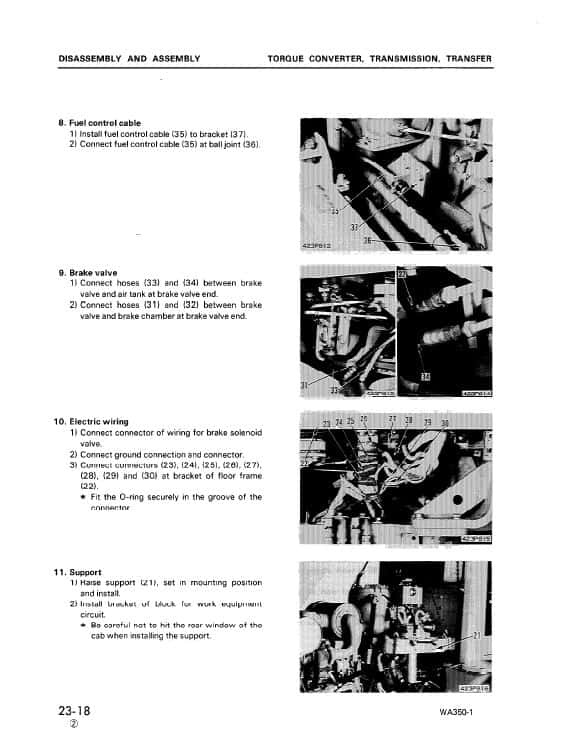

40 STEERING SYSTEM

41 STRUCTURE AND FUNCTION

42 TESTING AND ADJUSTING

43 DISASSEMBLY AND ASSEMBLY

44 MAINTENANCE STANDARD

50 BRAKE AND AIR SYSTEM

51 STRUCTURE AND FUNCTION

52 TESTING AND ADJUSTING

53 DISASSEMBLY AND ASSEMBLY

54 MAINTENANCE STANDARD

60 WORK EQUIPMENT SYSTEM

61 STRUCTURE AND FUNCTION

62 TESTING AND ADJUSTING

63 DISASSEMBLY AND ASSEMBLY

64 MAINTENANCE STANDARD

80 ELECTRIC AND ELECTRONIC SYSTEM

81 STRUCTURE AND FUNCTION

82 TESTING AND ADJUSTING

83 DISASSEMBLY AND ASSEMBLY

90 OTHERS

91 STRUCTURE AND FUNCTION

93 DISASSEMBLY AND ASSEMBLY

97 GEAR PUMP